What is SUBLAND drill?

When I proceeded with delivery, suddenly I saw the word “subland” on the package.

What is SUBLAND?

Not Lego land, nor Puroland? (Duh!)

That sounds kind of cute, so I decided to research about it.

The notable point of SUBLAND drill

So, what is SUBLAND drill?

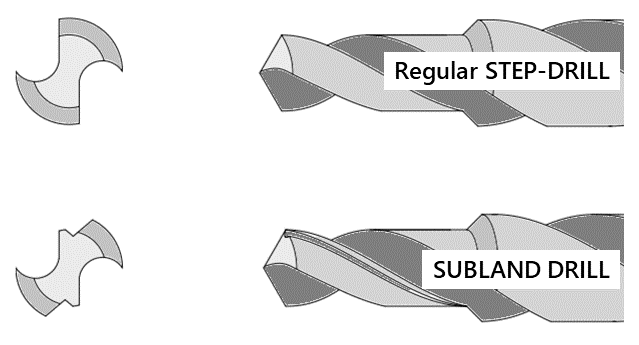

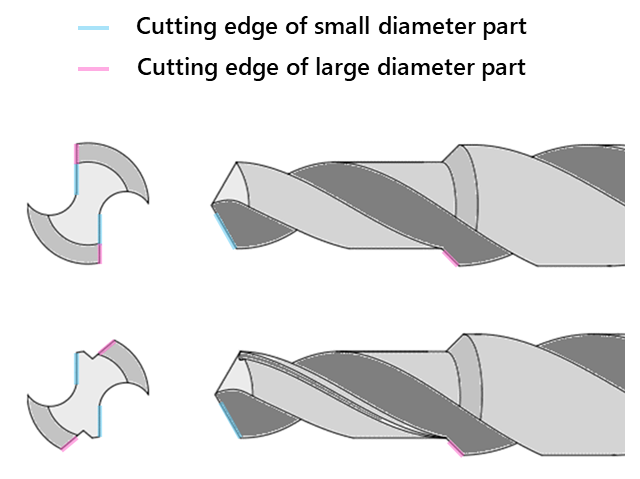

This is a multi-fluted step drill with a groove on the large diameter and a groove on the small diameter.

The cutting edge of the small diameter part is designed to be separate from that of the large diameter part.

Hmm, I don’t really understand… (There weren’t as many cute elements as I expected…)

Let me try to decipher it bit by bit.

・A multi-fluted step drill with a groove on the large diameter and a groove on the small diameter

First, let’s talk about “having a groove of the small diameter part on the large diameter part”.

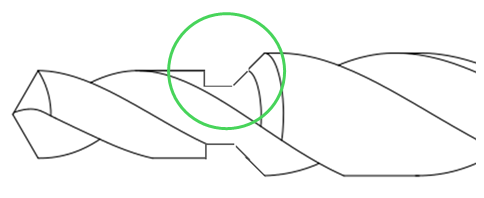

A regular stepped drill is compared to a sub-brand drill. It looks like this when drawn.

Here’s the difference.

It seems that the grooves that are not found in regular stepped drills are intentionally created in the small diameter part.

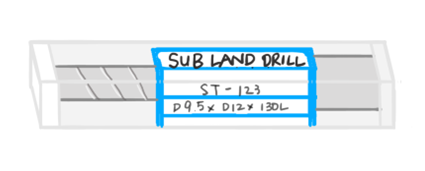

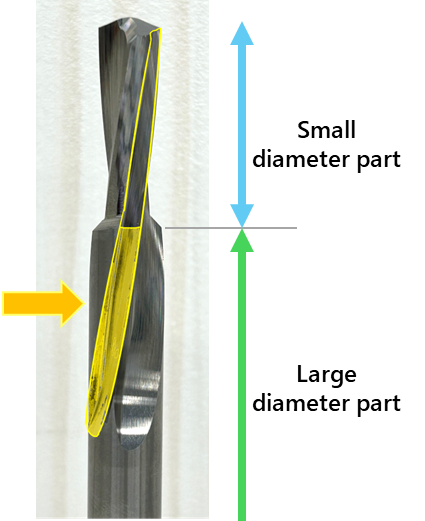

I was thinking that I would like to see the real subland drill,

and I found a brand-new subland drill in a good spot. So, I tried taking a photo.

Ah, that’s true. It’s hard to see, but there are definitely two grooves!

I’ll add some color.

|

Yellow part and |  |

blue part |

See, two grooves!

|

This yellow part is the groove intentionally made in the small diameter. |

|

This is the characteristic of a subland drill, “having a small diameter groove on a large diameter.”

OK, so far I understand.

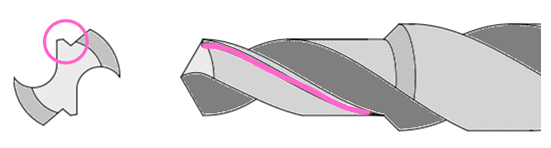

・The cutting edge of the small diameter part is separated from the cutting edge of the large diameter part

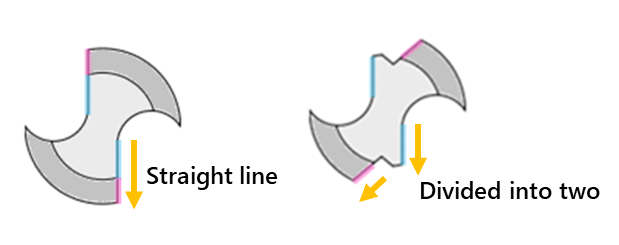

Next, what is a “separated cutting edge design”?

If we look at the cutting edge…

The cutting edge is divided into two thanks to the groove intentionally created in the small diameter part.

Yeah, now I know that this is what a subland drill looks like.

Now let’s explore the benefits of creating grooves in small diameter part!

Merit of creating grooves in small diameter part

There are two main merits to creating a groove in the small diameter part.

・Increase the number of regrinding

・Improve chip removal

Now let’s take a closer look.

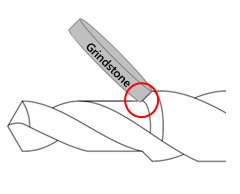

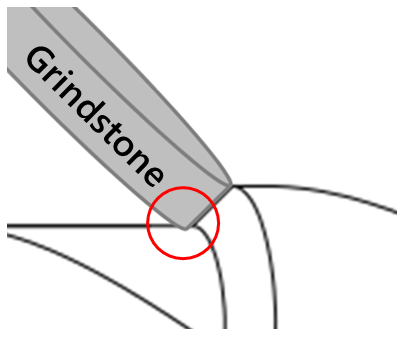

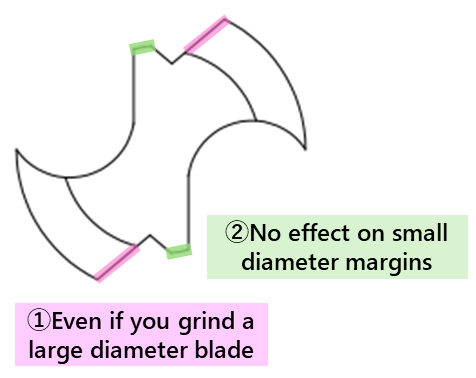

In the case of a regular stepped drill, when regrinding a large-diameter blade, the grindstone scratches the outer circumference of the small diameter.

It looks like this in illustration.

|

|

|

|

This large diameter blade has a great effect on the workpiece,

so it must be polished to the very edge.

So then, inevitably, there will be some scratches.

This is what it looks like if you exaggerate it.

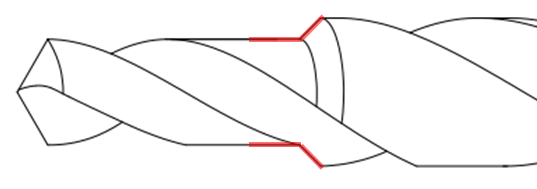

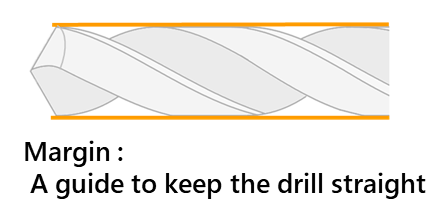

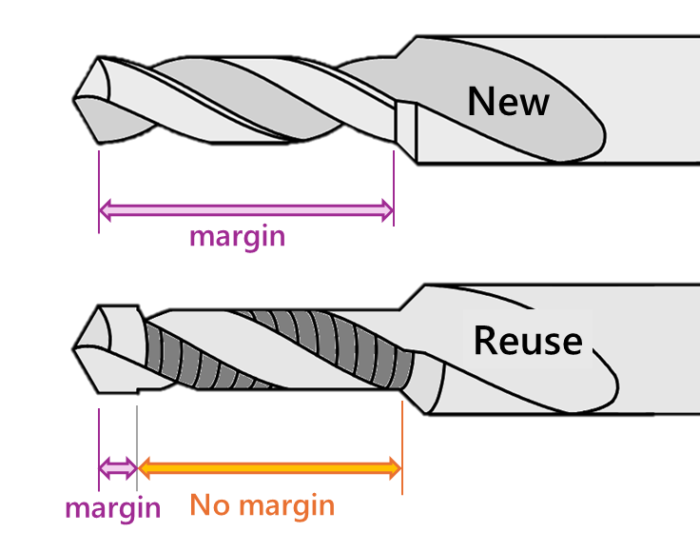

Drills have a “margin” that acts as a guide to keep it moving straight, but…

it has disappeared where the grindstone has dug into it.

If you repeat regrinding, this margin will become shorter and shorter.

Here’s how it looks compared to a new one:

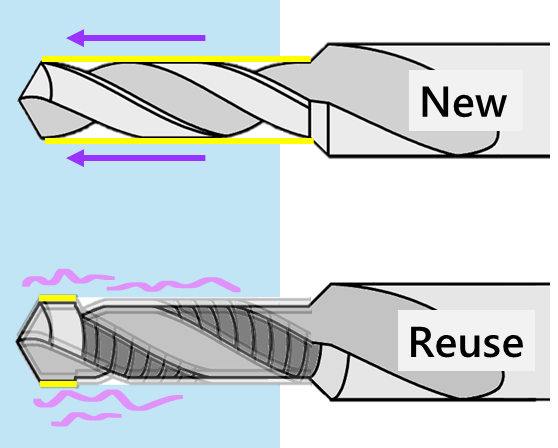

If the guide part becomes short, drill runout will occur.

If run-out occurs, machining will be unstable.

Well, that’s what happens when there’s no part to hold.

In the case of stepped drills, when the margin gets too short, it cannot be used as a drill anymore.

So, what about subland drills?

The subbrand drill regrinds in the same way as a regular stepped drill.

Because there are two grooves, the cutting edge is divided into two.

Subland drills have separate cutting edges, so when regrinding a large diameter blade,

the grindstone does not dig into the outer circumference of the small diameter.

So even if you repeat regrinding,

margins will not be shorter.

This means you can regrind it more times than a regular step drill!

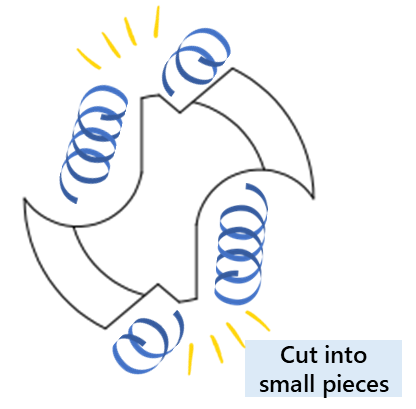

・Improve chip removal

Another merit of having two grooves is that they allow for better removal of chips.

Because the grooves are separated, the chips are broken down into small pieces.

The broken chips are smoothly discharged. Yeah!

Long, connected chips can get stuck in the hole and cause the drill to break.

It is nothing but a threat to tools.

It is very important to reduce the risk of chip clogging as much as possible.

Use for

Subland drills are mainly used for drilling pilot holes for screws and bolt holes.

It’s used as a pilot hole tool where hole accuracy is not required.

Use a lot, regrind a lot.

The subland drills manufactured by our company also often come back for regrinding.

Repeated “See you” and “Welcome back” So eco-friendly!

Demerit of SUBLAND drill

Subland drill that seems to have only good points.

Are there any disadvantages compared to a regular stepped drill?

When I looked into it

It seems difficult to manufacture because the shape is more complex than a regular stepped drill.

It is said designing a cutting tool requires extensive knowledge of not only the cutting tool but also the work material.

In addition to the difficulty of the design, the additional manufacturing process of “making another groove”

inevitably increases the price of the tool. (cost increase)

On the other hand, if the tool has high regrinding ability, it will last longer,

and the running costs will be reduced. (cost decrease)

Which should I choose, a regular drill or a subbrand drill?

Which one is better, overall?

It’s good for users to have choice.

As a tool manufacturer, we would like to continue to provide not only subbrand drills but also tools that have a variety of effects and are pleasing to users.